Summary

In this guide, I’ll walk you through everything you need to know about pre-treating viscose fabric for digital printing. Whether you’re a beginner or looking to improve your printing results, this step-by-step approach will help you achieve the beautiful, long-lasting prints you desire.

Introduction

Have you ever wondered why some printed fabrics look vibrant and last long, while others fade quickly or have uneven colors? The secret lies in proper pre-treatment. If you’re working with Viscose Digital Printing Fabric, understanding pre-treatment is essential for achieving professional, high-quality results.

Viscose fabric has become incredibly popular in digital printing because of its soft texture, excellent drape, and ability to absorb colors beautifully. However, without proper preparation before printing, you might face disappointing results like bleeding colors, uneven prints, or poor wash fastness.

Understanding Viscose Digital Printing Fabric Basics

Before diving into pre-treatment steps, let’s understand what makes viscose special. Viscose is a semi-synthetic fiber made from natural wood pulp. It feels like cotton but has a silky appearance similar to rayon. This unique combination makes it perfect for digital printing projects like scarves, dresses, and home textiles.

The main challenge with Viscose Digital Printing Fabric is its high absorbency. While this helps colors look rich and vibrant, it also means the ink can spread unpredictably without proper treatment. Think of it like painting on paper versus painting on canvas the surface preparation makes all the difference.

Without pre-treatment, you might encounter several problems. The ink might bleed beyond the design edges, creating blurry images. Colors may appear dull or uneven across the fabric. Worst of all, the print might wash out after just a few laundry cycles. Pre-treatment creates a controlled surface that helps ink sit exactly where you want it, resulting in sharp, vibrant, and durable prints.

Essential Pre-Treatment Steps

Fabric Inspection and Preparation

The first step is often overlooked, but it’s crucial for quality results. Start by carefully examining your viscose fabric under good lighting. Look for any stains, oil spots, or manufacturing defects. These imperfections will show up in your final print, so it’s better to catch them early.

Next, remove any dust, loose fibers, or lint from the fabric surface. You can do this with a soft brush or a lint roller. Even tiny particles can interfere with ink absorption and create spotty prints.

Make sure your fabric is properly relaxed and not stretched. If the fabric has been tightly rolled or folded, let it rest flat for a few hours. This prevents distortion in your printed design later.

Pre-Washing Process

Pre-washing is a critical step that many beginners skip, but it makes a huge difference. Viscose fabric often contains sizing agents, oils, or other finishing chemicals from the manufacturing process. These substances can block ink absorption and cause printing problems.

Fill a large container or washing machine with lukewarm water around 30 to 40 degrees Celsius (86 to 104 degrees Fahrenheit). Hot water can damage viscose fibers, so keep the temperature moderate. Add a small amount of mild, pH-neutral detergent. Avoid fabric softeners, bleach, or harsh chemicals.

Gently wash the fabric for about 10-15 minutes. Don’t agitate it too vigorously, as viscose can be delicate when wet. After washing, rinse thoroughly with clean water to remove all detergent residue. Any leftover soap can interfere with the pre-treatment chemicals you’ll apply next.

For drying, avoid wringing or twisting the fabric, which can damage the fibers. Instead, gently squeeze out excess water and lay the fabric flat or hang it to dry naturally. If you must use a dryer, choose the lowest heat setting. The goal is to have clean, completely dry fabric ready for the next step.

Chemical Pre-Treatment Application

This is where the magic happens. Pre-treatment solution is a special chemical mixture that prepares the fabric surface to accept digital printing ink properly. For Viscose Digital Printing Fabric, the pre-treatment solution typically contains ingredients like sodium alginate, urea, and sometimes soda ash.

You have three main methods to apply pre-treatment:

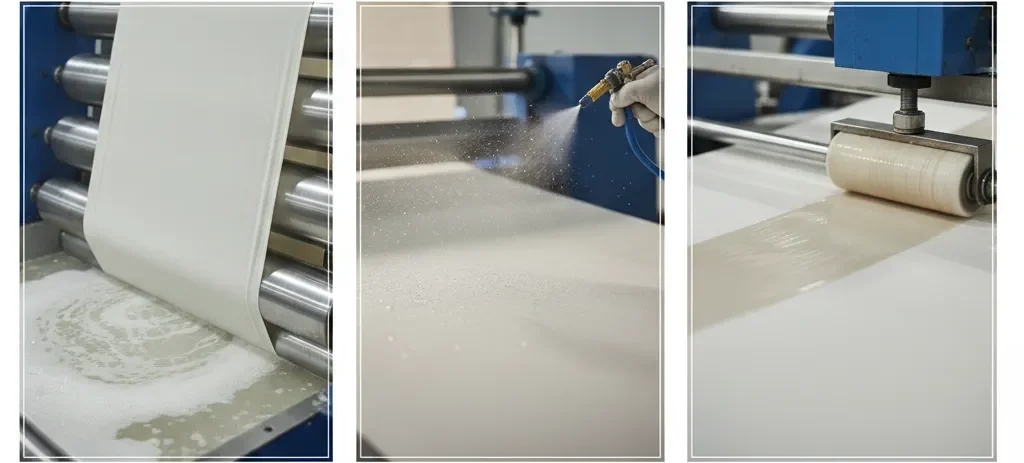

Padding method: This involves passing the fabric through rollers that evenly distribute the pre-treatment solution. It’s the most professional method and gives the most consistent results, but requires special equipment.

Spraying method: Using a spray bottle or spray gun, you can apply the solution evenly across the fabric surface. This works well for smaller projects and home-based operations. The key is to maintain consistent distance and overlap your spray pattern to avoid streaks.

Coating method: You can use a foam roller or brush to apply the solution. This gives you good control but requires practice to achieve even coverage.

Regardless of your method, the general mixing ratio is about 50-100 ml of pre-treatment concentrate per liter of water, though this varies by product. Always follow the manufacturer’s instructions for your specific pre-treatment solution.

Apply the solution evenly across the entire fabric surface. Too much solution will make the fabric too wet and may cause bleeding; too little won’t provide adequate treatment. The fabric should feel damp but not soaking wet.

Drying and Curing

After applying the pre-treatment solution, proper drying is essential. The goal is to remove the water while leaving the treatment chemicals evenly distributed on the fabric fibers.

The ideal drying temperature for viscose is between 100-140 degrees Celsius (212-284 degrees Fahrenheit). You can use a heat press, conveyor dryer, or even a household iron on medium-high heat. If using an iron, place a protective cloth between the iron and fabric.

Drying time varies depending on your method and fabric thickness, but generally takes 3-5 minutes with heat. The fabric should feel completely dry to the touch with no damp spots.

After heat drying, let the fabric rest for at least 30 minutes before printing. This allows the treatment chemicals to fully settle and bond with the fibers. Some professionals recommend waiting 2-4 hours for optimal results.

Check the moisture content the fabric should contain about 5-8% moisture for best printing results. Too dry, and the ink won’t absorb properly; too wet, and colors will bleed.

Best Practices for Pre-Treating Viscose Digital Printing Fabric

Now that you know the basic steps, here are some professional tips to ensure success:

Create a checklist and follow it every time. Consistency is key in pre-treatment. Write down your specific measurements, temperatures, and timing so you can replicate good results.

Always test a small sample first. Before treating an entire roll of fabric, pre-treat a small piece and print a test pattern. This helps you verify that your process works correctly and allows you to adjust if needed.

Work in a clean, dust-free environment. Any contamination during pre-treatment can ruin your prints. Keep your work area clean and store pre-treated fabric in sealed bags.

Common mistakes to avoid include using too much pre-treatment solution, which causes stiffness and bleeding, or applying it unevenly, which creates inconsistent print quality. Also, never skip the pre-washing step those manufacturing chemicals will cause headaches later.

Store pre-treated Viscose Digital Printing Fabric properly. Keep it in a sealed plastic bag away from moisture, dust, and direct sunlight. Use pre-treated fabric within 2-3 weeks for best results, as the treatment effectiveness decreases over time.

Troubleshooting Common Pre-Treatment Issues

- Uneven ink absorption: If some areas print darker than others, your pre-treatment application was likely uneven. Solution: Pay more attention to consistent application, possibly switching to the padding method for better uniformity.

- Color bleeding: If your printed designs look blurry with colors spreading beyond edges, you’ve applied too much pre-treatment solution or didn’t dry it sufficiently. Solution: Reduce the solution concentration slightly and ensure thorough drying.

- Fabric stiffness: If the fabric feels too stiff after pre-treatment, you’ve used too much chemical. Solution: Reduce your pre-treatment concentration and ensure even application with no thick spots.

- Poor wash fastness: If colors fade quickly after washing, the pre-treatment might not have cured properly, or you skipped the pre-washing step. Solution: Ensure proper curing time and temperature, and always pre-wash to remove interfering substances.

Expert Tips and Professional Insights

Professional textile printers emphasize the importance of record-keeping. Document your process details pre-treatment brand, mixing ratios, drying temperature, and time for each successful batch. This creates your personal recipe for success.

For cost-effectiveness, buy pre-treatment solutions in bulk if you work on multiple projects. However, always check the shelf life and storage requirements.

To save time while maintaining quality, consider investing in a foam applicator or small padding machine if you regularly work with Viscose Digital Printing Fabric. The initial investment pays off in consistency and time saved.

Environmental considerations matter too. Choose pre-treatment solutions with fewer harsh chemicals when possible. Properly dispose of any waste water according to local regulations, and consider water-saving techniques like minimal rinsing when appropriate.

Conclusion

Pre-treating viscose fabric properly is the foundation of successful digital printing. By following these steps inspection, pre-washing, chemical treatment, and proper drying you’ll achieve professional-quality prints with vibrant colors and excellent durability.remember, practice makes perfect. Your first few attempts might need adjustment, but once you find the right process for your specific situation, you’ll consistently produce beautiful prints on Viscose Digital Printing Fabric.

If you’re looking for quality Viscose Digital Printing Fabric to practice these techniques, EthirajFashion offers reliable fabric options for digital printing enthusiasts and professionals alike.