Introduction

The world of fabric and textile printing by far transforms in 2025. The industry, powered through consumer demand and eco-friendly processes coupled with digital technology advances, has moved far beyond the rotary and screen printing limitations. Creative freedom, sustainability, versatility, and speed are now provided by digital fabric printing beyond prior dreams.

In this in-depth article we uncover what’s new and next in digital textile printing. Smart manufacturers, designers and also suppliers can stay right ahead in what is an increasingly competitive tech-driven market because all of these innovations matter so much for brands and for consumers.

The Evolution of Digital Fabric Printing

From Screen to Digital: A Brief History

Previously, print-making on fabric worked on screen printing which is traditionally a manual or mechanized way of transferring designs using mesh screens. Screen printing is effective for producing the same design continuously using large amounts of fabric, but it comes with its drawbacks: high initial costs, excess chemical and water usage, and little capacity to do custom or short-run work.

Digital fabric printing began to put a dent in this system in the early 2000s when inkjet and dye-sublimation printers were first introduced, but these early systems were often too slow and lacked any good level of color fastness. By 2025, digital fabric printing had come so far in direct-to-fabric (DTF), direct-to-garment (DTG) and hybrid print technology, that most of the speed and color discrepancies were resolved.

Breakthrough Printing Technologies in 2025

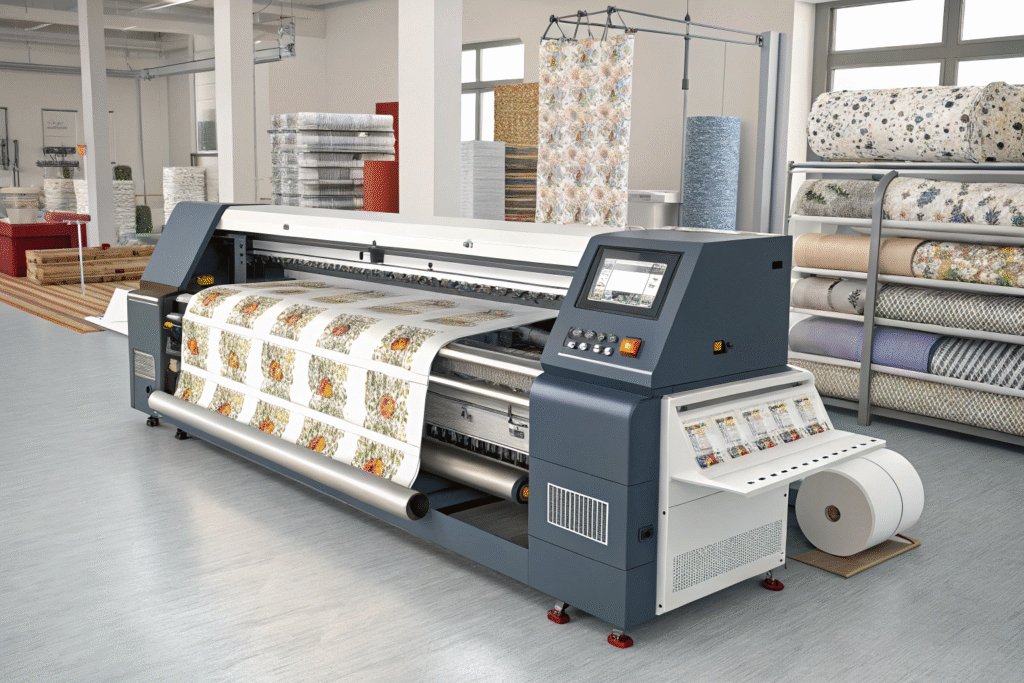

High-Speed Direct-to-Fabric Printers

2025’s leading innovation is the rise of ultra-fast DTF printers. Machines like EFI Reggiani’s “Hyper” and Mimaki’s latest TX series print meters of fabric per minute, with consistent, bold color, and reduced consumable waste. Modern printheads improve droplet accuracy, minimizing banding and enabling complex, photorealistic designs.

Benefits:

- Efficient short and long runs

- Minimal setup time

- Supports both natural and synthetic fabrics

Waterless and Eco-Friendly Printing Processes

Environmental responsibility is now a necessity. Modern textile printers are using pigment inks that are waterless; therefore, they are reducing the pollution, runoff waste and company resources. Kornit Digital leads the industry with hybrid systems that couple waterless inks with little to no pre-treatment, practically eliminating each company’s air and water footprints.

What’s new:

- Pigment-based inks with improved wash and light fastness

- In-line curing and fixation, eliminating post-process washes

- Smarter pre-treatment that consumes less energy and chemicals

Expanded Color Gamuts and Special Effects

Modern printers are not only faster than the early generation of printers, but they also offer more colors and more print possibilities. To illustrate, 8 and 10 color channel printers, neon and metallic inks, and advanced software that allows the printer to halftone based on the variation in shades and colors are now available; designers can now achieve colors that were previously unimaginable on fabric.

On-Demand and Custom Printing Platforms

The “Amazon effect” reached the textile industry as consumers now expect unique and personalized products at rapid speed through on-demand manufacturing. In 2025, a new reality will emerge where many microfactory and on-demand textile businesses will proliferate; They will leverage printers that are connected via the cloud and use AI applications to accelerate the process from design to shipping within a few days.

Automation, AI & Digital Workflow Integrations

Automated Design-to-Print Pipelines

Thanks to the new generation of AI-powered design tools, digital designs can be moved to printed outcomes in record time and with zero errors—from digital design through to printing. Products like Adobe Textile Designer, and other advanced RIP (Raster Image Processor) software, facilitate colour management, file preparation and the management of print queue—to name just a few processes. This massively reduces valuable time and provides enhanced accuracy while eliminating the possibility of a reprint or wastage due to errors.

Real-Time Monitoring and Predictive Maintenance

New textile printing machines are no longer just machines, they are IoT-enabled and share data on performance, maintenance and consumable levels in real time. Predictive analytics can learn how and when machines do breakdown and will predetermine failure – enabling highly productive downtime. This helps to facilitate “lights-out” or fully automated (no human assistance) operations that take place during unsociable hours.

Vertical Production & Smart Microfactories

The microfactory is bringing all stages—design, printing, cutting, sewing—into a distinctly digitally connected environment. Brands can now get from digital file to finished garment in hours. It also supports a higher level of vertical integration which allows local production, smaller-inventory and delivery of ultra-fast restocks to end-consumers while maintaining an overall lower environmental footprint.

Sustainability and Green Innovation

Eco-Friendly Inks and Materials

2025’s consumers and brands demand sustainability. Eco-certifications like OEKO-TEX®, GOTS, and BLUESIGN® are now essential for global suppliers. Many digital printing ink manufacturers now prioritize:

- Water-based, low-VOC pigment/dye-sublimation inks

- Inks made from natural or recycled materials

- Biodegradable and recyclable print substrates

Waste Reduction Through Digital Practices

Digital printers produce very little waste compared to analog methods. No need for screens, plates, or excessive sample runs. Automated nesting algorithms optimize designs on fabric, further reducing off-cuts.

Circular Production Models

Forward-thinking printers are working on “take-back” programs for used fabric, recycling polyester substrates, and upcycling waste fabric into new products.

Seed keywords: sustainable digital textile printing, eco-friendly fabric inks, textile waste reduction

Customization, Personalization, and the Rise of D2C

Why Personalization Matters

Millennials and Gen Z shoppers desire clothes and home textiles that are one-of-a-kind and show off their personalities. In 2025, brands will be able to sell made-to-order designs that are all different. With print-on-demand, small businesses can compete with big companies without having to keep a lot of pricey stock.

Platforms Enabling Mass Personalization

With new e-commerce connections like Shopify, Printful, and Spoonflower, people can design fabric online, see it in 3D, and order it with fast pricing. APIs link designs straight to factories, where digital printers make orders as needed.

Case Study: Success in Custom Printed Fabrics

Digital platforms are used by home decor stores, sports teams, and small fashion designers to make custom-printed products in full color and get them to customers quickly. With little alteration to the workflow, smart “digital dye houses” can handle orders of any size, from one to thousands.

Smart Textiles and Functional Printing

What Are Smart Textiles?

Smart textiles use electronics, special inks, and fabric to make clothes that “do” something, like glow, sense, react, or change color. In 2025, big breakthroughs will be made in conductive inks, thermochromic dyes, and microencapsulation.

Applications in Health, Fashion, and Sports

Printed sensors can now keep track of things like body temperature, heart rate, and posture. Fashion companies employ digital printing to make clothes that change color. Printed coatings that shield UV rays and kill germs are used on sportswear.

The Intersection of Digital Print and Wearable Tech

Digital fabric printers make it possible to apply responsive materials with great accuracy, which opens up new possibilities for interactive clothes, accessories, and technological fabrics.

Challenges and Opportunities in 2025

Scaling Up: From Sample to Mass Production

It’s easy to run short distances, but it’s still hard to run 10,000 meters or more with flawless consistency. New ideas in calibration, quality control, and managing printheads are helping to close this gap.

Ensuring Color Accuracy Across Batches and Materials

Textile printing is hard since the color changes depending on the type of fabric, its thickness, and its chemistry. In 2025, AI-powered calibration tools and enhanced color profiling will make sure that cotton, polyester, mixes, and specialized fabrics are all accurate.

Workflow Integration With Traditional Processes

A lot of manufacturers employ hybrid processes, which mix digital and analog to get the best of both worlds. For example, they might use digital for short runs with plenty of colors and screen for big monochrome works. Modern ERP and MES systems connect all the steps so that manufacturing goes smoothly.

The Skills Gap and Talent Development

As factories become more automated, workers need to learn new things like graphic design, file management, fixing software problems, and color science. Top organizations put money into training and teams that work across disciplines.

The Competitive Edge: How Leading Companies Are Succeeding

Investing in the Right Technology

Top-ranking textile printers don’t just buy machines—they build digital ecosystems that link customers, designers, and production centers worldwide, ensuring reliability, flexibility, and rapid response.

Building Flexible, Sustainable Supply Chains

The ability to quickly pivot, launch new designs, or meet sudden surges in demand is a direct result of investment in digital printing and local microfactories. Sustainability and transparency are key selling points, attracting more brands and buyers.

Collaborating with Artists and Designers

The creativity unlocked by digital textile printing is helping manufacturers make unique collaborations with artists, influencers, and emerging brands. Limited editions, capsule collections, and artist-driven prints are now mainstream.

Seed keywords: digital textile printing advantages, sustainable supply chain, designer collaboration textile printing

The Future of Digital Fabric Printing: What’s Next?

- AI-Designed Patterns: AI will create new, trend-driven prints and colorways in real time, predicting market demand.

- Ultra-Sustainable Fabrics: More fabrics will come from recycled and regenerative sources, printed with biodegradable inks.

- Hyperlocal Production: Expect near-instant, local production hubs bringing fabric design and delivery closer to the consumer.

- Integration with AR/VR: Customers will preview fabric and products virtually, tweaking colors and patterns before manufacturing.

- Fully Circular Systems: The digital print ecosystem will reclaim, recycle, and remake fabric with minimum waste.

Seed keywords: future of digital fabric printing, AI textile design, circular textile manufacturing, AR VR textile shopping

Conclusion and Takeaways

Digital fabric printing in 2025 is a world away from the past—faster, more sustainable, creative, and connected than ever. The key innovations driving this growth are high-speed direct-to-fabric machines, eco-friendly ink technology, seamless digital workflows, and the ability to personalize at scale. Overcoming challenges in color management, scaling, and workforce training will be critical for ongoing success.

What businesses should do next:

- Invest in modern digital print platforms with proven eco-credentials.

- Embrace on-demand and personalized production models.

- Focus on developing digital skills and integrating design-to-print workflows company-wide.

- Build sustainability and transparency into supply chains.

Consumers and brands alike now expect a blend of eco-consciousness, speed, and creativity from their textile suppliers. Those who lead in digital printing innovation will be best positioned for the future of fashion, interiors, and smart products.